Application of Computer Vision Methods for Automated Wooden Planks Length Measurement

IEEE

Authors: L. Zabulis, A. Lipnickas, R. Augustauskas

Published in: 2022 18th Biennial Baltic Electronics Conference (BEC)

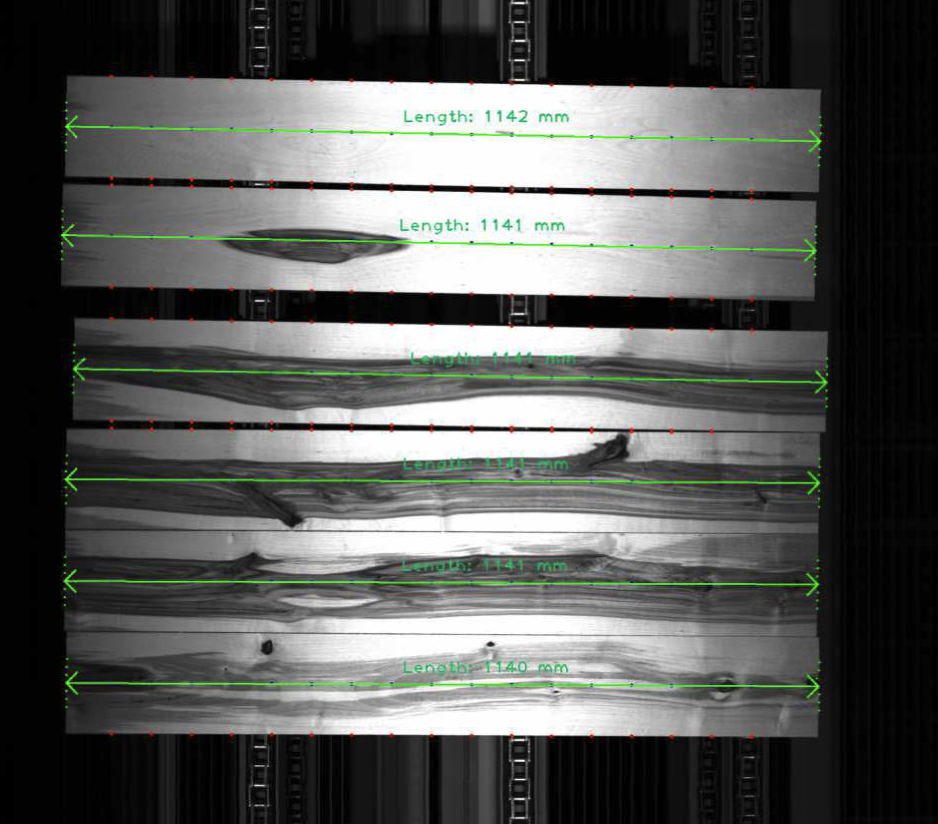

Abstract: Automated inspection is a principal component in modern manufacturing aiming for Industry 4.0. With the fast development of digital image processing and machine learning algorithms, quality control is often performed by computer vision systems (CV). Following the presented topic, this paper applies the CV system for non-direct length measuring of objects moving through a conveyor. The approach involves image segmentation by a convolutional neural network and segmented object processing principles. Since high-resolution images were used, segmentation was performed in a patch manner. The algorithm also involves a custom contour analysis and the application of the least-squares method for the midline of wooden plank extraction. The proposed approach is robust to the object’s non-alignment and merging factors as well as shape and wooden texture variance. The presented algorithm was tested on a custom wooden planks database gathered in a real EURO pallets production environment and confirmed to work as expected ensuring ±1mm length measuring accuracy and 0.97s processing timing meeting the real-time requirement of the specified system.